What is an Arc Flash?

An Arc Flash is a type of electrical discharge as a result of a low-impedance connection through the air between two conductors.

An Arc Flash is a type of electrical discharge as a result of a low-impedance connection through the air between two conductors.

Also, it is typically caused by accidental contact, dropping tools, insulation failure, condensation or dripping water, dust, as well as corrosion of equipment parts.

Particularly, an Arc Flash can release large amounts of energy and produce intense heat, reaching up to 20,000° Celsius. Indeed, this is four times the surface temperature of the sun.

Why is Arc Flash analysis essential?

An Arc Flash study is an engineering investigation for identifying the specific AF hazard of any given piece of equipment.

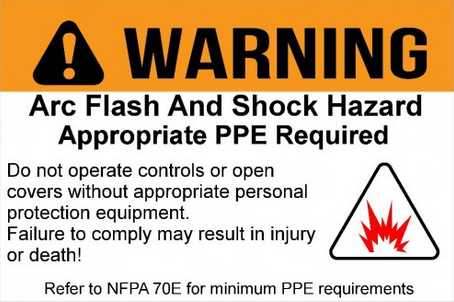

In addition, several regulations, codes and standards define requirements for AF safety, such as OSHA, NFPA 70E, CSA Z462, and NESC.

Particularly, article 130.5 of NFPA 70E requires employers to perform an AF risk assessment for electrical equipment in order to identify all AF hazards present and to update the study at intervals not to exceed five years.

So, a regular update of the Arc Flash study will ensure compliance with codes and regulations as well as safeguarding personnel and the electrical installations.

Why Phoventus?

- Firstly, it is Convenient; Phoventus offers full-wrap services such as a site visit, modelling, report and recommendation, label printing and affixing

- Cost-effective; Phoventus offers customizable solutions that allow for controlling service cost without paying for unnecessary tasks

- Specialized in PV and wind power plants AF assessment

- Industry standard AF assessment Software ETAP 19.1

- Customer-focused and dedicated services

List of Arc Flash Services:

- Site visit for data collection and verification

- AF hazards analysis

- Fault current calculation

- Protective device coordination study

- Personal Protective Equipment selection

- AF label printing and / or Installation

- AF hazards mitigation strategy

- Educating personnel on hazard awareness

- Training personnel on how to work within acceptable limits